Sheet laser metal cutting

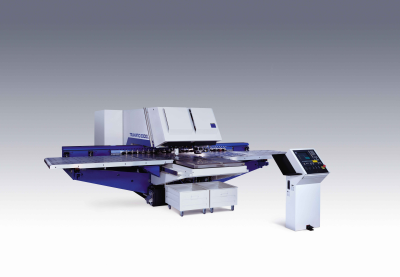

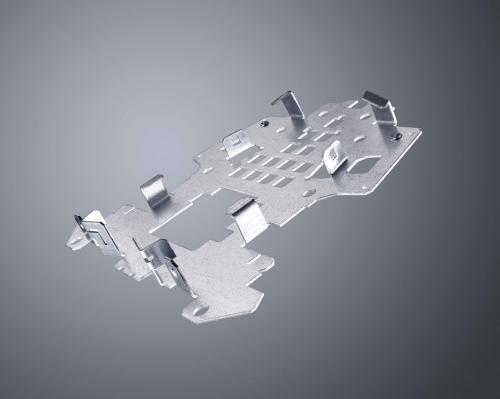

We offer comprehensive services in the field of sheet metal CNC processing, laser cutting of sheet metal, sheet metal punching, and bending of sheet metal using a press brake, all of this using TRUMPF machines. We also offer welding using the CO2 or TIG method, spot welding, and, for larger series, we have robotic welding available – a CLOOS welding robot. Welding and pressing of elements (nuts, bolts, and the like) into sheet metal is a matter of course for us. The comprehensiveness of our services is further supplemented by our powder coating shop. For the sake of completeness of our range of services, the assembly of parts and products must be mentioned, including electrical installation – wiring of boxes and switchboards, functional testing, and ensuring all required certificates.

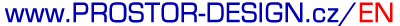

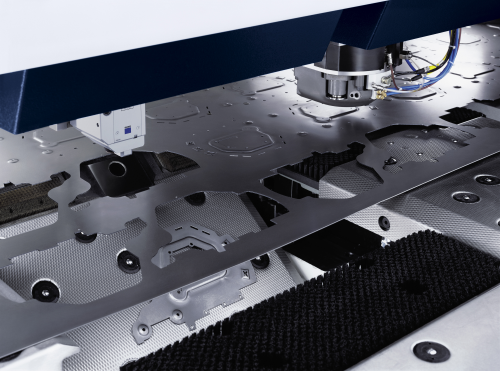

The TRUMPF TruMatic 6000 machine offers a combination – 2D laser cutting of sheet metal and punching of sheet metal in one production operation, including all advantages consisting in forming and shaping by the punching machine. Compared with the standard laser cutting of sheet metal, this machine is limited because it is able to cut material thick up to 6 mm only. Therefore, we can call it a laser for cutting thin sheet metal.

Compared with classic technologies, CNC laser cutting or the CNC cutting of material using a laser is always substantially more advantageous and brings substantial savings as regards the costs of production of parts. This modern laser sheet metal shape cutting technology replaces classic sheet metal machining technologies.